Countrywide Installation!

6 New Features of the Sveaverken F100 Spring Version

Galileo PPP

In an auto steer system, the correction source plays a crucial role in providing accurate positioning data for the automated steering functionality. As one of the correction sources available since 24/01/2024, Galileo PPP is suitable for users who do not have a nearby reference station to provide network data and have not purchased a mobile base station. Compared to other correction sources we support, the biggest advantage of Galileo PPP is that it is free, does not need network connectivity, but still ensures an accuracy of about 10cm.

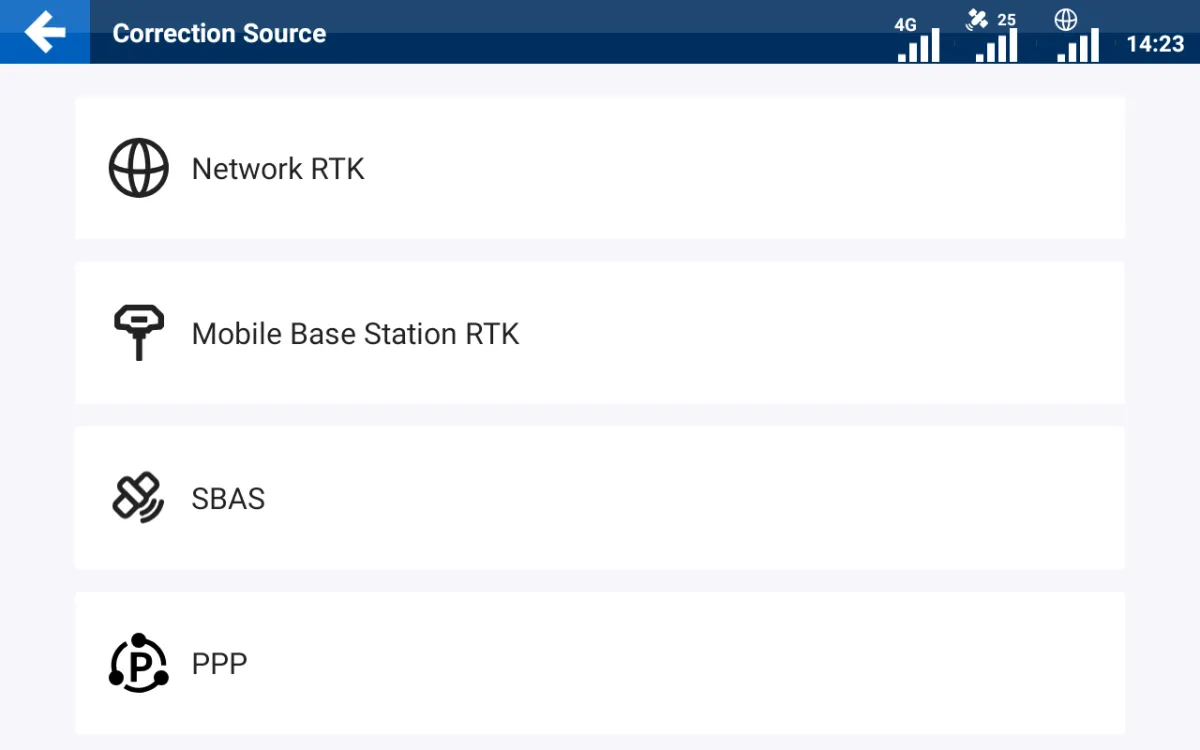

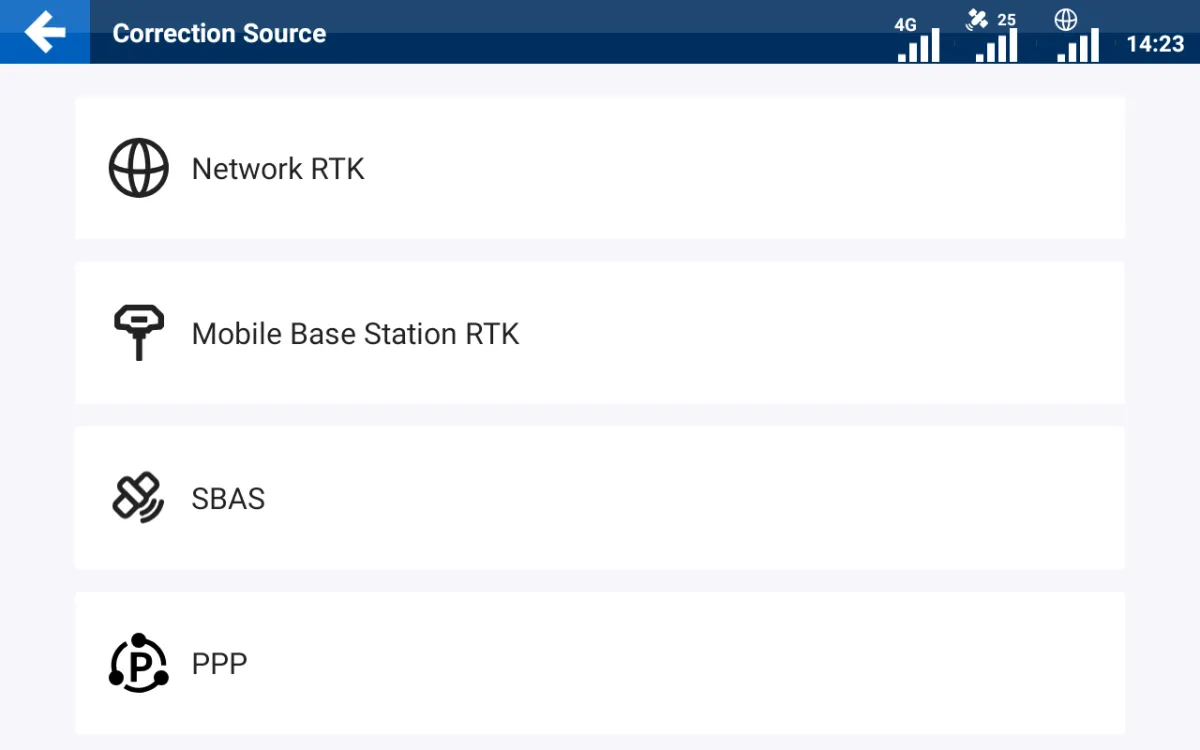

To activate Galileo PPP, follow these simple steps:

Go to Menu, tap Device Settings

Choose PPP from Correction Source

Super Low Speed

When performing delicate tasks that require precision at low speeds, the

Super Low Speed mode has got you covered. Whether you're sowing seeds

or spraying crops, this feature ensures accuracy and stability when

operating at speeds below 1 km/h.

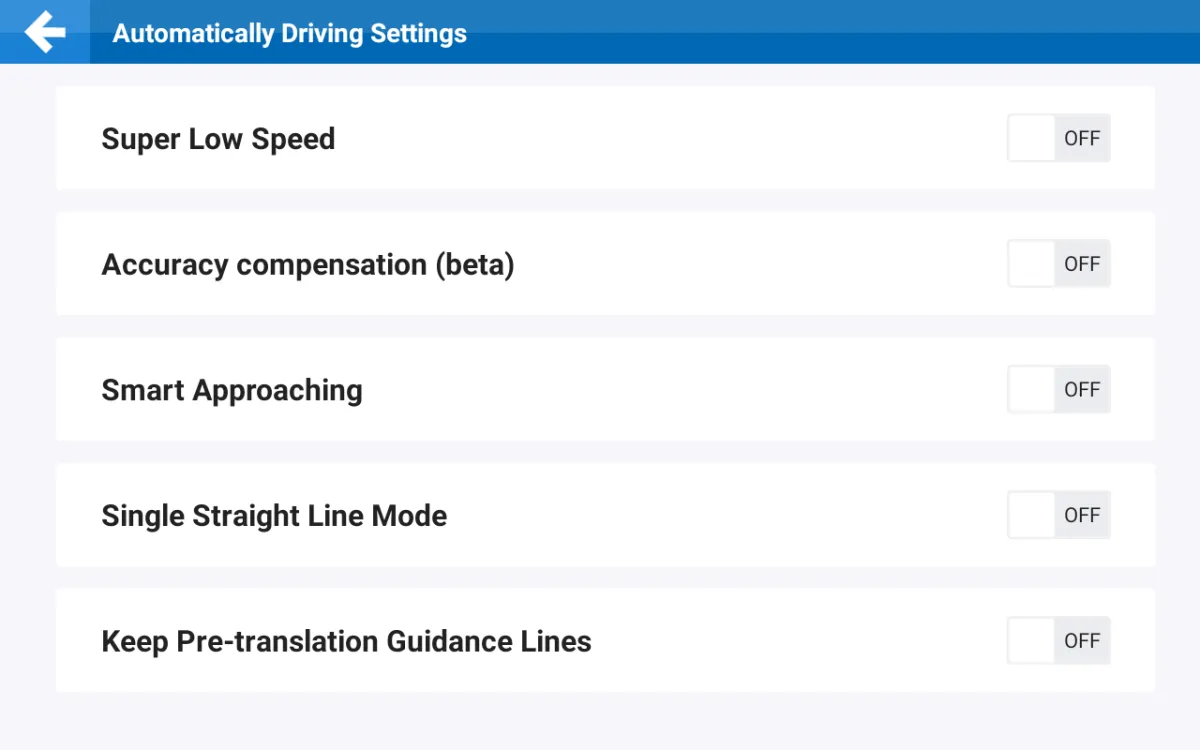

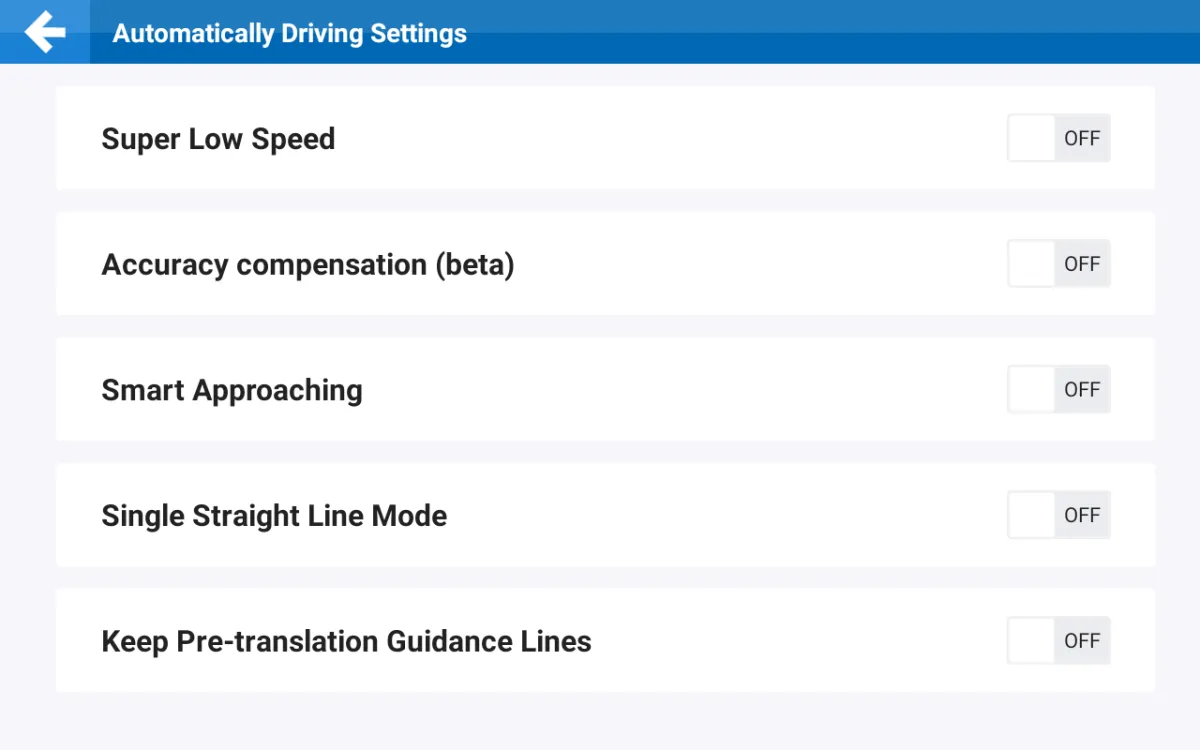

To activate Super Low Speed, follow these steps:

Go to Homepage - Menu

Go to Menu - Device Settings

Go to Automatically Driving Settings, enable Super Low Speed

Currently, the following speed modes are supported:

Super Low-Speed mode: 0.1km/h-1km/h (0.03m/s-0.3m/s)

Normal mode: 1km/h-18km/h (0.3m/s-5m/s)

High-speed mode (with precision compensation beta): up to 26km/h

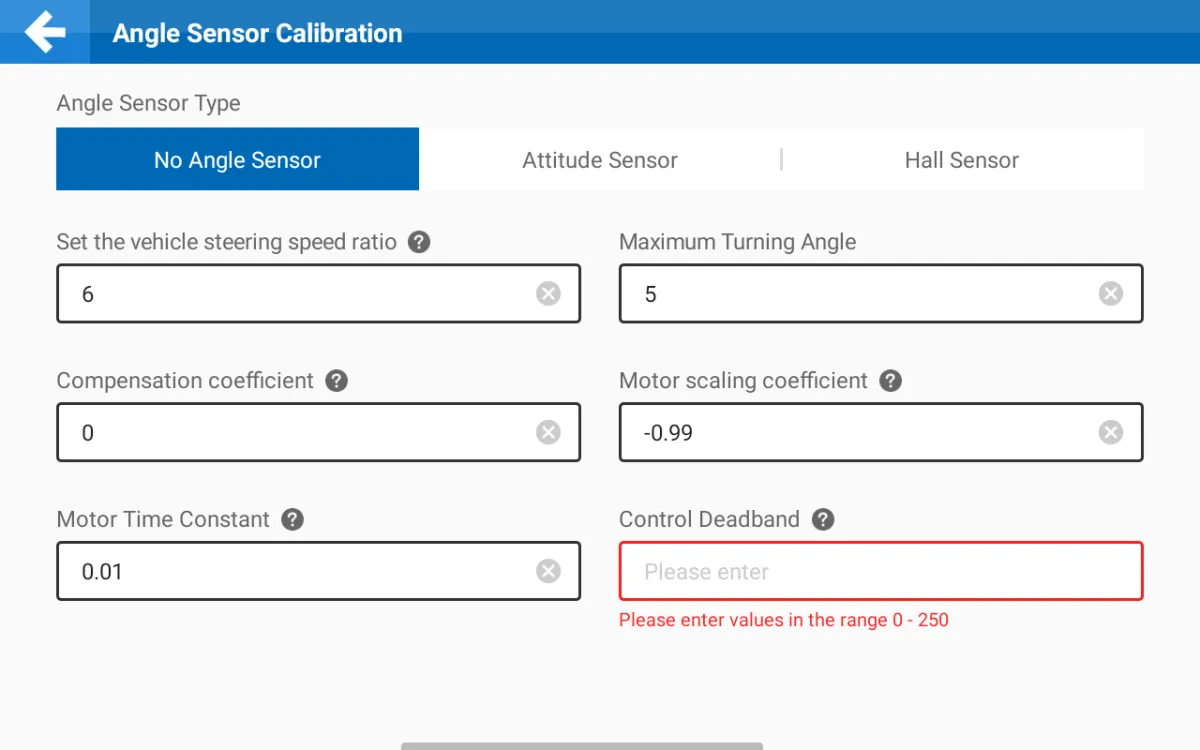

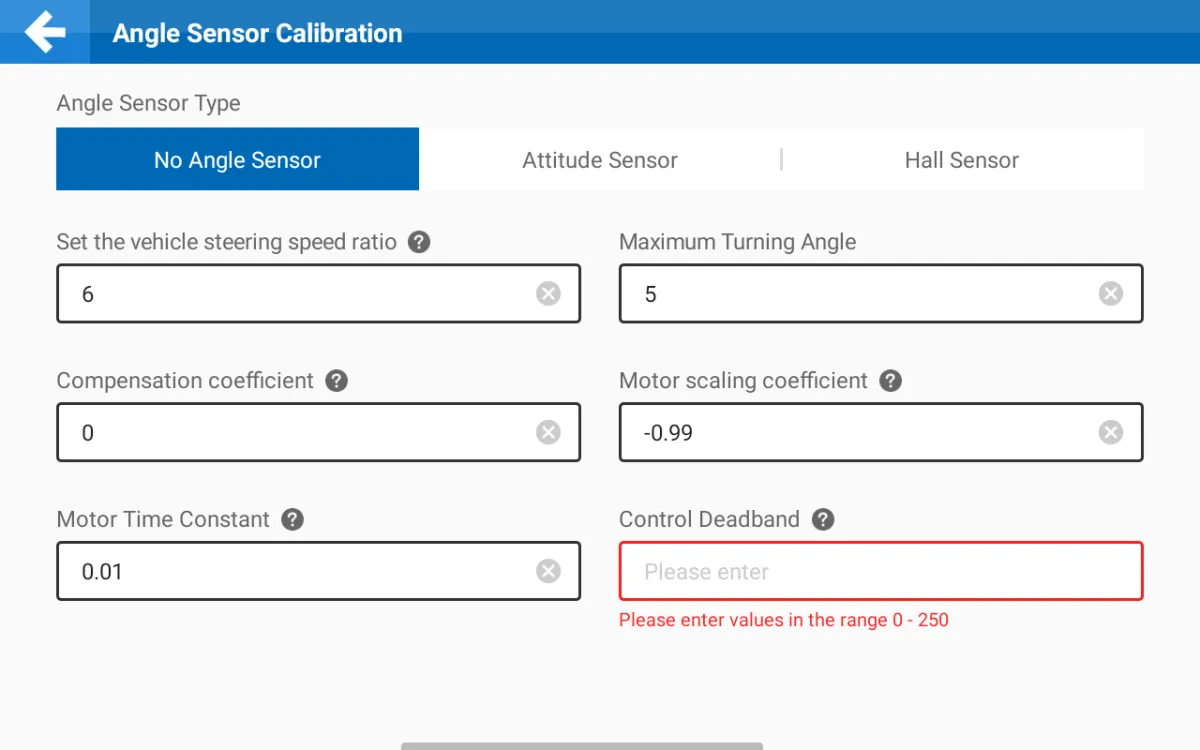

Deadband Settings

Have you faced the issue of turning the steering wheel without the drive

wheels rotating? If so, this feature is designed for you if you use a

no-angle sensor.

In the context of tractors and agricultural machinery, the deadband

refers to a specific range of steering wheel movement that does not

translate into any actual turning of the wheels. With the Spring Version,

just input the deadband values where the steering wheel does not work

when you want your tire steering.

To configure Deadband Settings, follow these steps:

Go to Homepage and tap Menu

Go to Device Settings and then Angle Sensor Calibration

Choose No Angle Sensor and input your desired deadband value

Tap Calibration to save the settings

Note: The value you need to input is the sum of the left and right deadband degrees, that is, the degree at which the steering wheel rotates from the center to the left and right, but the tires do not turn.

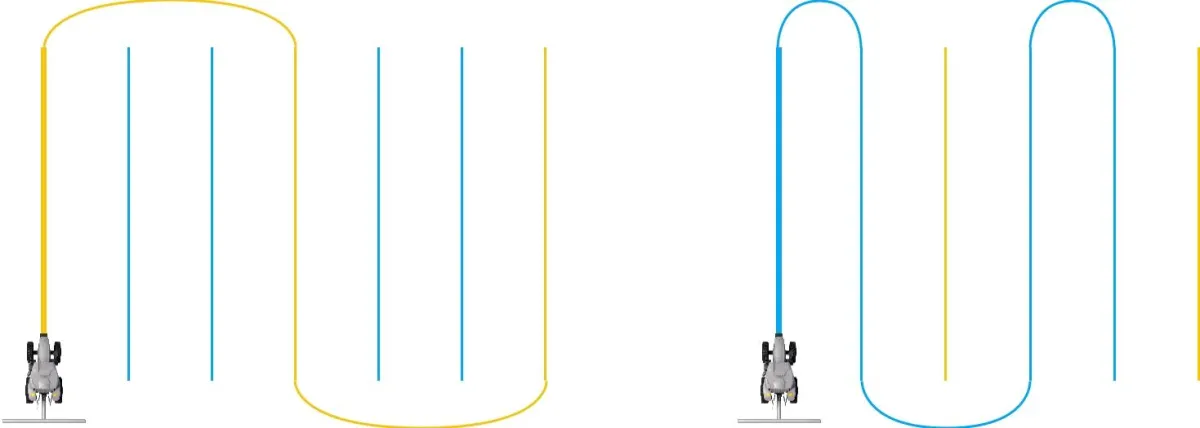

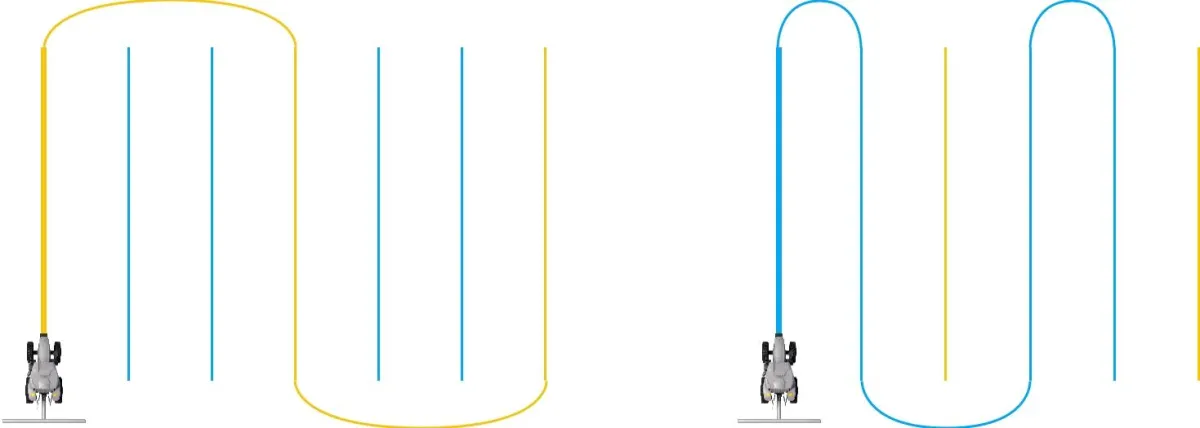

Tramline

In crop farming, not trampling plants is crucial for successful

cultivation and yield. However, plant protection machinery, like

tractor-mounted sprayers, often inadvertently damage seedlings during

operation due to the lack of designated lanes for subsequent plant

protection.

With the new Tramline feature, lanes for plant protection can be marked

in yellow under the blue guidance line and seeding operation width.

These lanes will remain un-sown, allowing for periodic plant protection

solely on Tramlines to prevent seedling damage. Harvesting operations

will then be carried out exclusively on the blue guidance line to

enhance efficiency.

To use Tramline, follow these steps:

Go to Menu - Field Settings

Choose Guidance Line

Tap Tramline for setting

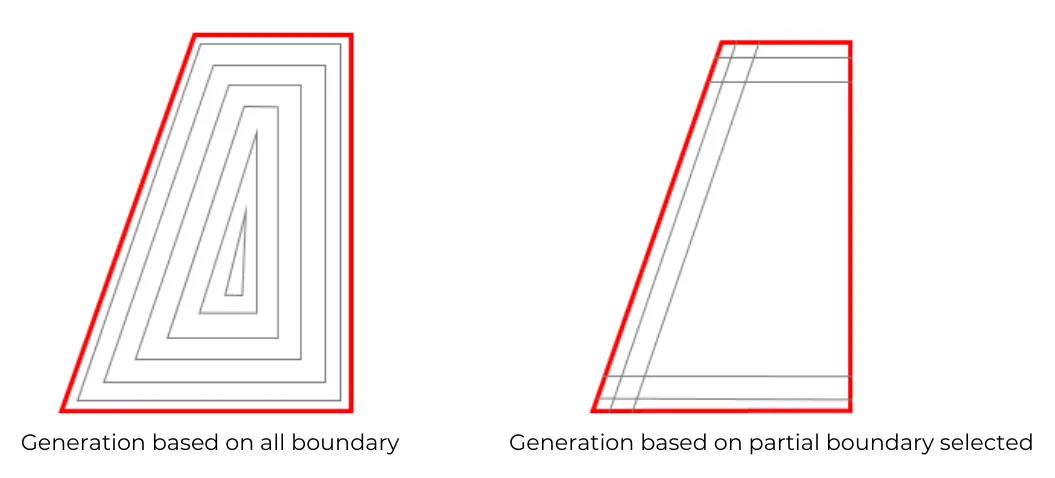

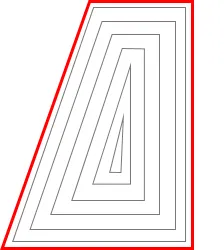

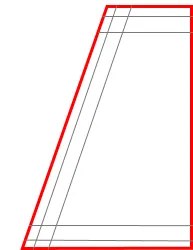

Headland (Advanced Mode only)

Traditional guidance lines can't cover all the space in irregular

fields, such as a trapezoidal-shaped field, leading to low land

utilization. The Headland feature enables you to generate guidance lines

based on the shape of your field boundaries. Two types of generation

modes are available, so you can choose the guidance line layout that

works best for your field conditions.

Generation based on all boundary

Generation based on partial boundary selected

To use Headland, follow these steps:

Go to Menu - Application Settings

Go to Automatically Driving Settings, choose Guidance Line Type, and tap Headland

Return to Homepage and go to Create Interface to generate headland guidance lines

ISOBUS

We understand the importance of seamless communication and compatibility

between different pieces of equipment. That's why the Spring Version

introduces ISOBUS support, enabling smooth integration between tractors

and implements from different manufacturers. With ISOBUS, you can

control various implements using a single display, the F100 Control

Terminal, eliminating the need for multiple implement-specific displays

in your tractor cabin.

Universal Terminal (UT)

Simplifying agricultural implement management, the UT allows farmers to control various implements from different brands using a single display. Through CAN message exchange, the UT initializes and displays the implement's user interface, reducing the need for multiple implement-specific displays in the tractor cabin

Task Controller Basic (TC-BAS)

TC-BAS records essential work-related metrics such as total area covered

and total application based on implement data. This recorded data can

be effortlessly exported for documentation and seamlessly shared between

farm management systems and task controllers, facilitating efficient

data flow and informed decision-making processes.

To upgrade and activate ISOBUS functionality, please refer to the official documentation or contact our support team for detailed

instructions.

Facebook

Instagram

TikTok